Professional Eyewear

Manufacturing Solutions

One-Stop Eyewear Manufacturing Specialist serving global brands with precision craftsmanship, innovative technology, and uncompromising quality standards.

Looking for a Reliable Eyewear Manufacturing Partner?

VISO combines decades of manufacturing expertise with cutting-edge technology to deliver exceptional eyewear solutions that exceed global quality standards and drive your business success.

20+ Years Manufacturing Excellence

Two decades of precision manufacturing experience serving global eyewear brands

Vertically Integrated Production Chain

Complete control from design to delivery ensuring quality and efficiency

Serving 50+ Countries Worldwide

Global reach with local expertise and international quality standards

Complete Product Ecosystem

From Concept to Mass Production

Our comprehensive OEM/ODM services transform your eyewear concepts into market-ready products with precision engineering and quality assurance.

Design Consultation

Understanding your vision and technical requirements through expert consultation

Prototype Development

Rapid prototyping and iterative design refinement for optimal performance

Quality Testing

Rigorous testing protocols ensuring products meet international standards

Mass Production

Scalable manufacturing with consistent quality and on-time delivery

Get Your Custom Quote in 24 Hours

Professional consultation with detailed specifications and competitive pricing

Complete Guide to Eyewear Manufacturing

Master the complete eyewear manufacturing process from concept to production with our comprehensive 10-chapter guide covering everything you need to know as a professional buyer.

What is Professional Eyewear Manufacturing

Frame Types & Applications

Lens Categories & Technologies

Materials Guide & Selection

OEM vs ODM Manufacturing Models

Customization & Branding Services

Factory Tour & Capabilities

Cost Factors & Pricing Structure

Order Process & Lead Times

How to Choose Your Manufacturer

Ready to start your eyewear manufacturing journey?

Chapter 1: What is Professional Eyewear Manufacturing

Dive deep into the core elements of modern eyewear manufacturing industry, exploring how one-stop manufacturing model redefines industry standards

Eyewear Industry Manufacturing Chain Analysis

Raw Material Sourcing

Acetate fiber, metal, titanium alloy and other high-quality materials

Design & Development

3D modeling, ergonomics, aesthetic design

Precision Manufacturing

CNC machining, laser welding, surface treatment

Quality Control

Multi-level inspection, optical testing, durability verification

Packaging & Delivery

Custom packaging, brand identification, global logistics

VISO Manufacturing System Introduction

Based on 20 years of manufacturing experience, VISO has built a complete vertically integrated manufacturing system, providing professional eyewear manufacturing solutions for global customers

VISO Core Manufacturing Capabilities

Chapter 2:Frame Types & Application Scenarios

Comprehensive eyewear solutions designed for diverse market segments and professional applications

Optical Frames Classification

Business Collection

Professional image enhancement with premium materials including titanium, stainless steel, and high-grade acetate for corporate environments.

- • Classic rectangular & oval shapes

- • Premium titanium & metal alloys

- • Sophisticated color palettes

- • Executive comfort features

Fashion Collection

Contemporary designs targeting young demographics with bold aesthetics, vibrant colors, and innovative materials for style-conscious consumers.

- • Oversized & geometric designs

- • Colorful acetate combinations

- • Trendy patterns & textures

- • Youth-oriented styling

Sports Collection

Functional eyewear solutions engineered for active lifestyles with durability, flexibility, and performance-oriented features for athletic applications.

- • Impact-resistant materials

- • Flexible TR90 construction

- • Anti-slip grip technology

- • Sweat-resistant coatings

Sunglasses Frame Classification

Classic Collection

Timeless designs with enduring appeal featuring iconic shapes like aviators, wayfarers, and round frames that transcend seasonal trends.

- • Iconic aviator & wayfarer styles

- • Premium metal & acetate

- • Neutral color schemes

- • Universal appeal designs

Trendy Collection

Fast-fashion inspired designs following current market trends with bold shapes, gradient lenses, and statement-making aesthetics for fashion-forward consumers.

- • Oversized & cat-eye shapes

- • Gradient & mirror lenses

- • Bold color combinations

- • Instagram-worthy designs

Functional Collection

Performance-oriented sunglasses engineered for outdoor activities with specialized features like polarization, UV protection, and impact resistance.

- • Wraparound sport designs

- • Polarized lens technology

- • UV400 protection standard

- • Anti-glare coatings

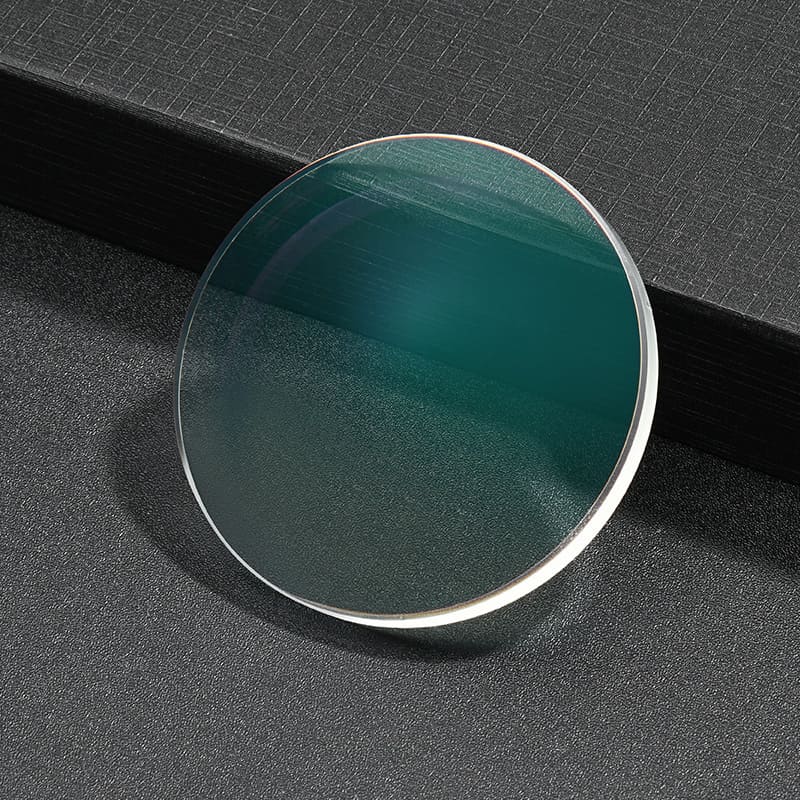

Chapter 3: Lens Categories & Technical Applications

Comprehensive guide to lens types with detailed functionality comparison and market positioning

Basic Lens Types

Single Vision Lenses

Myopia & Hyperopia Correction

- Uniform prescription power

- Cost-effective solution

- Wide compatibility

Progressive Lenses

Presbyopia Solution

- Seamless vision transition

- No visible line separation

- Premium aging solution

Bifocal Lenses

Traditional Multi-focal

- Distinct distance/near zones

- Affordable multi-focal option

- Easy adaptation

Functional Lens Hot-selling Types

Blue Light Blocking

Market Demand Analysis

Photochromic Lenses

Convenience Advantages

Polarized Lenses

Driving Specialist

Anti-Radiation

Professional Demand

Lens Function Comparison & Price Range

| Lens Type | UV Protection | Blue Light Block | Anti-Glare | Durability | Price Range (USD) |

|---|---|---|---|---|---|

| Single Vision | ★★★ | $15 - $45 | |||

| Progressive | ★★★★ | $85 - $280 | |||

| Blue Light Blocking | ★★★★ | $35 - $95 | |||

| Photochromic | ★★★★★ | $65 - $185 | |||

| Polarized | ★★★★ | $45 - $125 | |||

| Anti-Radiation | ★★★★ | $40 - $110 |

Chapter 4: Material Guide & Selection Recommendations

Comprehensive material analysis with comparison tables to help you make informed decisions for your eyewear manufacturing needs

Frame Materials Deep Analysis

Acetate Fiber

Classic ChoiceAdvantages:

- • Excellent color variety and patterns

- • Hypoallergenic properties

- • Superior comfort and flexibility

Considerations:

- • Requires careful maintenance

- • Higher manufacturing cost

Titanium Material

Premium MarketAdvantages:

- • Ultra-lightweight construction

- • Superior corrosion resistance

- • Premium durability and strength

Considerations:

- • Higher price point

- • Limited color options

Stainless Steel

Cost-Performance BalanceAdvantages:

- • Excellent value proposition

- • Good durability and strength

- • Wide market acceptance

Considerations:

- • Heavier than titanium

- • Potential skin sensitivity

TR90 Material

Sports Eyewear PreferredAdvantages:

- • Superior flexibility and impact resistance

- • Lightweight and comfortable

- • Ideal for active lifestyles

Considerations:

- • Limited premium appeal

- • Fewer design variations

Lens Materials Comparison

| Material Type | Key Features | Best Applications | Market Position |

|---|---|---|---|

|

CR39 Resin

Standard Choice

|

|

General prescription eyewear, reading glasses, basic optical needs | Standard Market |

|

PC Material

Safety Focus

|

|

Children's eyewear, safety glasses, sports applications | Safety Segment |

|

High Index Materials

Thin Lens Solution

|

|

High prescription lenses, fashion eyewear, premium applications | Premium Market |

Chapter 5: OEM vs ODM Manufacturing Models

Choose the perfect manufacturing partnership model that aligns with your business needs and design capabilities

OEM Model

Original Equipment Manufacturing

Suitable Situations

Established Design Team Available

Perfect for brands with in-house design capabilities and clear product specifications

Service Content

Contract Manufacturing

Focus on production excellence based on your existing designs and specifications

Cost Structure

Relatively Lower Investment

Cost-effective solution with manufacturing-focused pricing model

MOQ Requirements

Relatively Flexible

Adaptable minimum orders to accommodate various business scales

ODM Model

Original Design Manufacturing

Suitable Situations

Design Support Required

Ideal for brands seeking comprehensive design and manufacturing partnership

Service Content

Design + Production Integration

Complete solution from concept development to final manufacturing

Cost Structure

Includes Design Investment

Comprehensive pricing covering design development and manufacturing

MOQ Requirements

Typically Higher Volume

Optimized for large-scale production runs and bulk orders

Quick Comparison Overview

| Aspect | OEM Model | ODM Model |

|---|---|---|

| Design Responsibility | Client Provided | VISO Developed |

| Time to Market | Faster | Comprehensive |

| Customization Level | Production Focus | Full Customization |

| Investment Level | Lower | Moderate |

Chapter 6: Customization Options & Brand Services

Transform your vision into reality with our comprehensive customization services, from design aesthetics to complete brand packaging solutions.

Appearance Customization Options

Color Customization

Pantone color matching system for precise brand alignment

Surface Treatment

Premium finishing options for enhanced aesthetics

Size Adjustment

Regional fit optimization for global markets

Decorative Elements

Premium embellishments for brand distinction

Packaging Customization Services

Eyewear Cases

Premium materials with custom design options

Cleaning Cloth

Brand printing services with premium microfiber

Instruction Manual

Multi-language versions for global distribution

Retail Packaging

Display-optimized packaging for retail environments

Chapter 7: Factory Tour - See Where Excellence is Made

Step inside our state-of-the-art manufacturing facility where precision meets innovation. With over 15 years of expertise, our vertically integrated production chain ensures every frame meets the highest international standards.

Our Manufacturing Process

Material Inspection

Rigorous quality control of raw materials including acetate, metal, and titanium components

Precision Molding

Advanced mold manufacturing with tolerances up to ±0.02mm for perfect frame geometry

Injection Molding

Temperature-controlled injection molding process ensuring consistent material density

CNC Machining

Computer-controlled precision cutting and shaping for intricate frame details

Surface Treatment

Premium finishing including polishing, anodizing, and protective coating application

Lens Assembly

Professional lens cutting, edging, and mounting with optical precision standards

Quality Control

Multi-stage inspection including dimensional, optical, and durability testing

Packaging & Logistics

Custom packaging solutions and efficient global shipping coordination

Inside Our Manufacturing Facility

Chapter 8: Global Success Stories

Trusted by leading brands worldwide, we've helped transform eyewear businesses across continents with our comprehensive manufacturing solutions and partnership approach.

Premium Fashion Brand Partnership

Collaborated with a leading European fashion house to develop their first eyewear collection, delivering 20,00+ premium acetate frames with custom branding and packaging.

Retail Chain Expansion Success

Supported a major Asian optical chain's rapid expansion with consistent supply of 200+ frame styles, enabling them to open 50 new stores across 3 countries.

Digital Transformation Journey

Helped traditional optical retailers transition to modern e-commerce with curated frame collections, dropshipping services, and digital marketing support.

What Our Partners Say

Hear from industry leaders who have transformed their businesses with VISO

"VISO's manufacturing expertise and attention to detail exceeded our expectations. Their ability to scale production while maintaining quality consistency was crucial for our global launch."

"The partnership with VISO transformed our supply chain efficiency. Their inventory management system and reliable delivery schedules enabled our rapid expansion across Asia."

"VISO didn't just provide products; they provided a complete business transformation solution. Their digital integration support was game-changing for our online presence."

Chapter 9: Order Process & Delivery Management

Streamlined workflow with transparent communication and reliable delivery timelines

Standard Order Process

Requirements Communication

Professional consultation and detailed requirement analysis

Sample Confirmation

Quality samples for approval and specification finalization

Production Progress

Real-time manufacturing updates and milestone tracking

Quality Control & Shipping

Rigorous inspection and secure packaging for delivery

Logistics Tracking

Complete visibility throughout the shipping journey

Delivery Timeline Strategy

Standard Products

Ready-to-manufacture designs with established specifications

Custom Products

Modified designs based on existing frameworks with customization

New Development

Complete new product development from concept to production

Chapter 10: How to Choose the Right Eyewear Manufacturer

A comprehensive guide to selecting the perfect manufacturing partner for your eyewear business success

Key Evaluation Metrics for Manufacturers

Production Capacity

- Monthly output volume & scalability

- Advanced equipment & automation level

Quality Control

- ISO, CE, FDA certifications

- Testing equipment & inspection protocols

Design Capability

- R&D team size & expertise

- Innovation cases & design portfolio

Service Response

- Communication efficiency & language skills

- Problem-solving speed & support quality

Business Reputation

- Client testimonials & case studies

- Partnership history & stability

Risk Avoidance Guide: Common Pitfalls

Quality Risks Behind Low Pricing

Extremely low quotes often indicate compromised material quality, outdated equipment, or hidden costs that emerge later in production.

⚠️ Red Flag: Prices 30%+ below market average

Delivery Promise Reliability

Assess manufacturer's track record of meeting deadlines. Unrealistic delivery promises can disrupt your entire supply chain.

⚠️ Red Flag: No production schedule transparency

Sample vs. Bulk Production Consistency

Ensure samples accurately represent bulk production quality. Request multiple samples from different production batches.

⚠️ Red Flag: Reluctance to provide batch samples

Intellectual Property Protection

Verify manufacturer's commitment to IP protection through comprehensive NDAs and anti-copying agreements.

⚠️ Red Flag: Unwillingness to sign IP agreements

Why Choose VISO as Your Manufacturing Partner

Compare our comprehensive advantages against industry standards

One-Stop Service

Reduce supplier management costs with our integrated design-to-delivery solution

Vertical Integration

Complete supply chain control delivers superior pricing and quality consistency

20 Years Experience

Two decades of expertise ensures stable, reliable partnership for long-term success

Quality Assurance

ISO, CE, FDA certified with multi-stage inspection protocols

Your Strategic Manufacturing Partner

Manufacturing Excellence

20+ years of precision manufacturing experience with state-of-the-art facilities and quality control systems.

One-Stop Service Value

Complete product ecosystem from design consultation to mass production and logistics support.

Partnership Commitment

Dedicated 24/7 support, flexible customization, and long-term strategic partnership approach.

VISO is more than a manufacturer – we're your strategic partner in building successful eyewear brands. Our commitment to quality, innovation, and service excellence ensures your products meet the highest standards while driving your business growth.

Start Your Partnership Today

🚨 Urgent Projects: Call +86-15962344520 (24/7 Hotline)

Get Your Custom Quote in 24 Hours

✅ Our Commitment to You:

- • Detailed quote within 24 hours

- • Free samples for qualified projects

- • Professional technical consultation

- • Transparent pricing with no hidden costs

🔒 Your information is secure and confidential